Owning a fleet of trucks means keeping it in good working order and preventive maintenance is key to ensure your vehicles are reliable at all times. Periodic maintenance by our team at Syntech ensures your fleet is working optimally. However, regular maintenance done in advance minimises the risk of breakdowns that could result in costly repairs and downtime for your business.

A well-maintained fleet lets your team get on with the job safely and efficiently with minimal interruptions. Fleet managers who schedule regular preventive maintenance for trucks can assure that the heavy-duty vehicles are operational at all times while keeping your business running smoothly.

Our preventative maintenance checklist outlines what needs to be done for proper fleet management so your truck drivers can perform their tasks stress-free and on time.

Preventive Maintenance for Trucks Checklist

#1. Check for Fluid Levels

Checking the fluid levels is one of the simplest ways to avoid serious problems that could lead to damage and costly repairs. This includes checking the truck’s coolant and engine oil as well as braking, power steering, and transmission fluids which only take a few minutes.

If the fluid levels are dropping between checks it’s an indication of either a leak or fuel consumption problem that needs to be fixed sooner rather than later. The video below demonstrates how to check your truck’s fluid levels.

#2. Change Fluids

While it’s tempting to get as much mileage as possible out of your truck’s fluids, the long-term cost could result in expensive and time-consuming breakdowns. How often you need to change fluids depends on a number of factors such as:

- How many kilometers your fleet travels every day

- The type of terrain your trucks traverse regularly

- The load weight and carrying capacity of the truck

When changing fluids, refer to the manufacturer’s guidelines for the correct procedure.

#3. Check Tire Pressure

The correct tire pressure is vital to prevent dangerous situations or damage to the truck when performing work tasks such as transporting loads from one site to another. Inflating tires to the right pressure minimises wear and tear as well as uneven tread which can result in blowouts.

Secure tire pressure maintains proper traction on the road while optimising fuel consumption and braking and load-carrying capacity at all times.

#4. Check Tires for Wear and Tear

Checking tires for wear and tear will give you a heads-up if there’s a problem. Uneven tread or worn rubber often indicates incorrect tire pressure or problems with the alignment or suspension of the truck. Replacing worn tires is necessary to prevent blowouts while booking on-site servicing will ensure your truck’s alignment or suspension is properly repaired.

Inspecting the tire condition and tread depth mitigates the risk of blowouts and poor handling of the truck that could result in serious accidents and work delays.

#5. Inspect Truck Brakes

Carrying a load requires skilled driving and a fully functioning truck. This includes a proper braking system that can handle loads on all types of terrains. Inspecting the truck brakes is a vital component of a preventative maintenance schedule and entails checking for even wear on both sides and front to the back of the brakes.

Frequent inspections of the truck brakes for minimum wear will tell you when you need to replace them as soon as possible! To ensure safe stopping, unbalanced brakes must be repaired or adjusted. Watch the video below which demonstrates how to perform brake inspection and do adjustments.

#6. Check Air Filters

Clean air filters guarantee better fuel economy as well as smoother-running engines. Clogged air filters reduce the amount of air going into your engine which impacts the power of the truck’s motor. Dirty air filters also increase fuel consumption.

Regular checks and replacing dirty or old air filters keep your trucks in shipshape condition. Even more so if they’re often driven on muddy or dusty roads!

#7. Battery Test and Electrical System Verification

Part of the fleet preventive maintenance plan should include an annual check on the trucks’ alternators, batteries, and electrical systems. If your truckers are traversing long distances with frequent stops, there’s a huge amount of strain put on the vehicle’s electrical system.

Battery tests and electrical system verification ensure everything is in good working order before the truck is taken out onto the road.

#8. Inspect the Gearbox and Clutch

Anyone in the trucking industry is no stranger to heavy workloads and this means keeping a fleet reliable and safe on the road when transporting goods. The gearbox is placed under a huge strain when a truck is carrying heavy loads and has high engine power. Regular gearbox inspections mean you catch major problems quickly and do repairs immediately.

Checking that the clutch isn’t slipping is vital for safe driving when carrying loads. Not only does a damaged clutch affect the reliability of the vehicle but it increases fuel consumption as well.

#9. Check Truck Lights

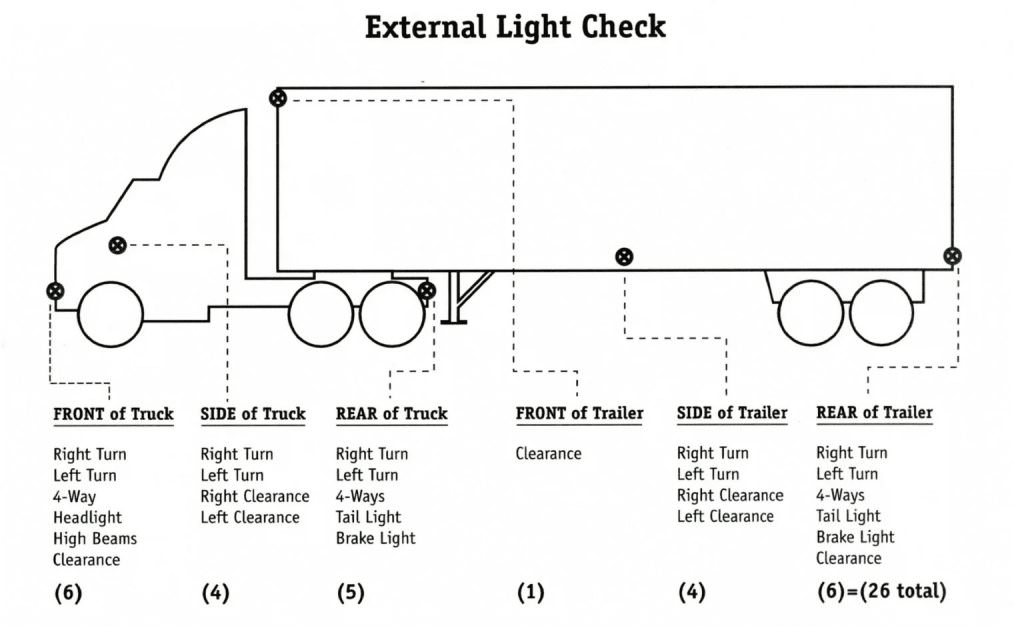

Being visible on the road when the weather is poor or at night time is essential for the safety of your trucker, vehicle, and other drivers. Part of your preventive maintenance schedule should include checking that the signal, hazards, and brake lights are working properly. Performing an inspection of the truck’s exterior lights should be done before each trip.

All it takes is a few minutes of walking around the truck, checking for burnt-out bulbs, and replacing them before hitting the road. Inspecting for broken light shields and replacing them helps to protect the bulb from further damage.

#10. Check for Body Corrosion

Road conditions, exposure to debris such as stones and debris as well as long-distance driving with heavy loads increase the risk of corrosion to your truck’s bodywork. Looking for signs of rust along the bottom of the door frames, on the undercarriage, and on the exhaust system will alert you to body corrosion.

Rust compromises the truck’s body structure which becomes a safety issue that needs to be fixed before it turns into a bigger problem. Otherwise, your truckers will face handling issues when faced with dangerous situations on the road. Repairing, modifying or replacing the rusted body parts is vital to avoid this from happening.

#11. Check for Parts That Need to Be Replaced

Ensuring that the heavy-duty vehicle is functional and safe on the road means you need to check for parts that need to be replaced. Before replacing parts make sure you order from a reputable supplier or truck manufacturer for premium-quality replacements.

The number of fatalities from traffic accidents in Singapore has risen in recent years and it’s imperative to keep your fleet functional to prevent becoming part of these statistics. It’s your responsibility to adhere to the trucking industry’s safety regulations and modifying or replacing parts that are outdated or damaged keeps your team secure when on the road.

Conclusion

Most truck drivers in Singapore aren’t trained or equipped to perform preventative maintenance and keeping a qualified technician on your payroll can be expensive. The best solution is to outsource fleet upkeep to a certified and reliable truck maintenance service company.

Let our professional maintenance team at Syntech Engineers do the job for you. We have the right equipment and servicing can be done on-site at your convenience too. We have the right parts in stock to prevent delays and downtime, making our services your solution for managing preventive maintenance tasks and servicing heavy-duty vehicles.

Prevention is always better than a cure, saving you from high repair costs or unexpected downtime that could have been avoided in the first place! If you found our list of preventive maintenance tips useful, forward it to other fleet managers who would benefit from reading this article.